CREATIVE MIND, CREATIVE WORKS.

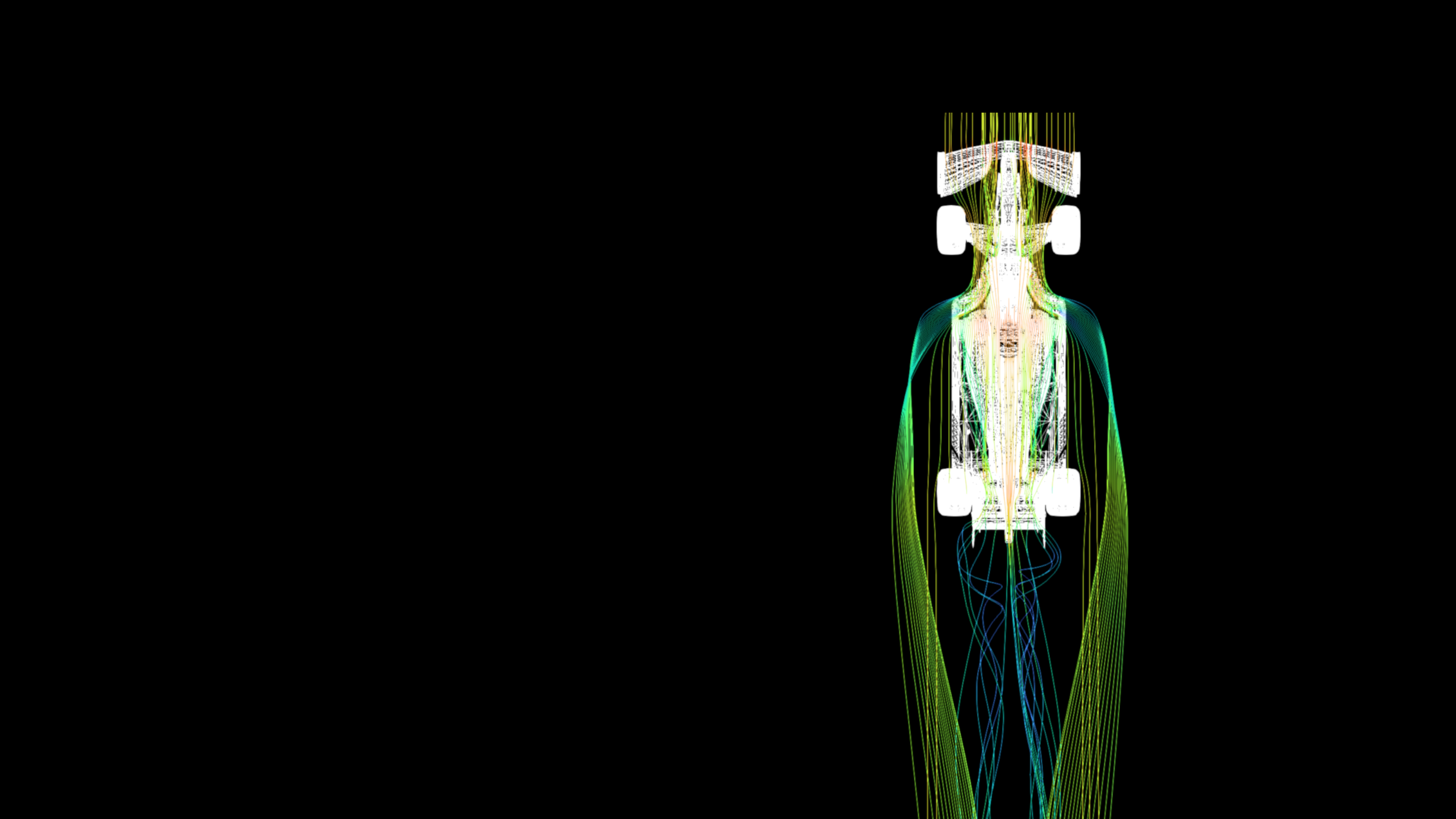

Simulating Reality

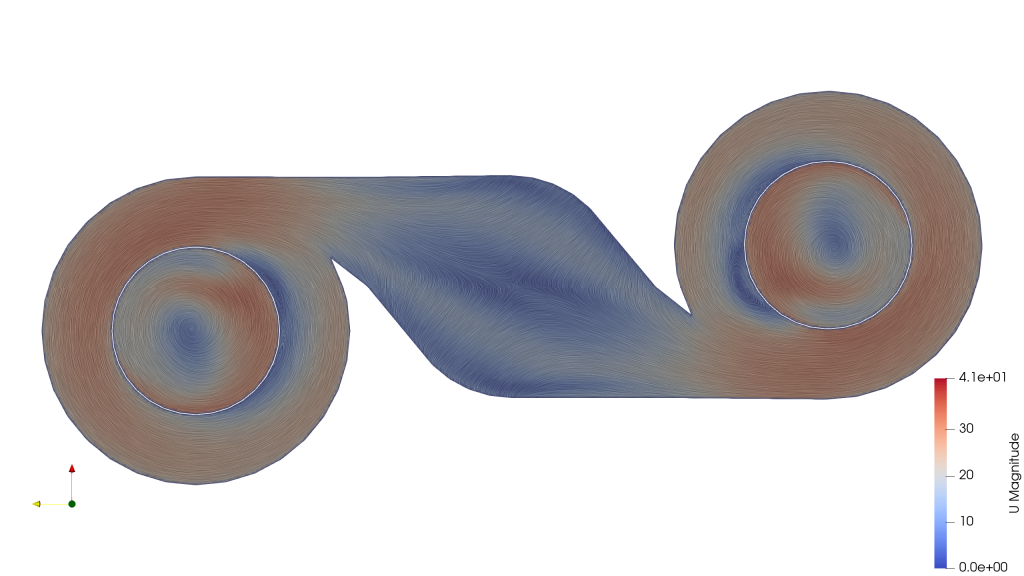

Computational Fluid Dynamics

We use CFD to simulation internal and external flow, as well as fire modeling and pyro-processing which we can use to simulate the formation of gasses such as CO2, CO and NOx.

Discrete Element Method

We use DEM to simulation material flow and motion. We can simulate the wear generated in a chute for example as well as determine the cause of blockages in bins and chutes.

Shape Optimization

We are able to leverage the latest shape optimizing techniques and algorithms to optimize objects to produce optimized shapes for the best aerodynamics possible.

Services

OUR SERVICES FOR CLIENTS

Internal Aerodynamics

We are able to simulate and analyze your duct for loses and optimize the path for the best flow possible to ensure you are able to use less power in your plant. We are also able to analyze optimize your bag filters to ensure even distribution of air and dust across the bag filter to increase bag life.

External Aerodynamics

From race cars, cars, buildings, planes, boats, and ships. We can simulate and analyze the flow around any object. We can provide improvements to the flow around the object to the customers’ requirements.

Fire Modeling

Fire prevention and safety is paramount in the modern era. We are able to model a fire that has occurred in various locations such as underground parking, pits, tunnels, underground mines etc. We can simulate the formation of harmful gasses and the distribution of them in the environment.

Bulk Material Flow

We simulate the flow through your chutes or bin to improve the movement of the material through your plant or equipment. We calibrate your material to ensure the flow is accurate then are able to model it in any use case.

Wear analysis

We are able to model the flow of material though a chute or some other transfer point and determine the areas of wear in the chute. From this we can pin point high areas of wears and make recommendations for liner configurations to reduce operation costs and downtime.

NOx, CO, and CO2 Formation

We are able to simulate your pyro process and determine the formation of gasses such a NOx, CO, and CO2. We can optimize your burning process to ensure optimal burning for your operating conditions.

Works

Projects We Have Done

About

Kyle Moon, Pr ENg

About Kyle

Kyle started his Engineering career at the University of Pretoria where he obtained his Bachelor of Engineering in Mechanical Engineering at the end of 2009. In 2010 he started working in the cement manufacturing industry. He has gained valuable experience in mining, crushing, conveying, milling, and burning processes. In 2013 He was fortunate enough to work in Tanzania and was an engineering on the construction of a new Clinker line, he was on the project from the civil construction work through to commissioning of the plant. In 2016 he registered as a Professional Engineer with the Engineering Council of South Africa. He always had a passion for simulations from CFD and DEM and his spare time he taught himself how to use a variety of simulating software. In 2023, once he had enough skill, he decided to start his own engineering consulting firm.